In offices, print shops, and industries that rely on high-volume document processing, efficiency and precision are non-negotiable. Enter the paper folding machine—a tool designed to automate one of the most tedious tasks in document preparation. But is investing in this equipment truly worth it? Let’s explore its features, benefits, and practicality to help you decide.

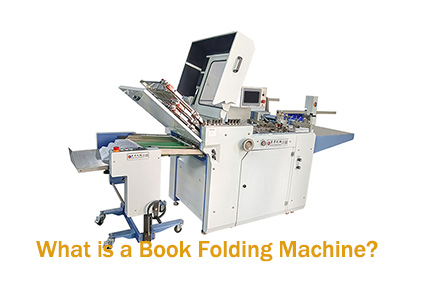

What Is a Paper Folding Machine?

A paper folding machine is a mechanical or electronic device that automates the process of folding paper into specific shapes and sizes. These machines are commonly used for creating brochures, letters, invoices, marketing materials, and other documents requiring uniform folds. They eliminate the need for manual folding, which is time-consuming and prone to errors.

Modern folding machines range from compact desktop models for small offices to industrial-grade systems capable of handling thousands of sheets per hour. Many integrate with printers, collators, or mailing systems for seamless workflow automation.

The Benefits of Using Paper Folding Machines

Time Savings: A folding machine can process hundreds of sheets per minute, far outpacing manual folding. For businesses handling bulk orders or frequent mailouts, this efficiency translates to significant labor cost reductions.

Consistency and Professionalism: Hand-folded documents often vary in alignment, crease quality, or symmetry. Machines ensure every fold is identical, enhancing your brand’s professional image.

Reduced Physical Strain: Repetitive folding tasks can lead to employee fatigue or injury. Automating this process promotes workplace safety and frees staff for higher-value tasks.

Versatility: Many folding machines support multiple fold types (e.g., C-fold, Z-fold, accordion fold) and accommodate various paper sizes and weights.

Cost-Effectiveness: While the upfront investment may seem steep, the long-term savings in labor, reduced waste, and increased productivity often justify the expense.

How to Use a Paper Folding Machine

Using a folding machine is straightforward:

Load the Paper: Adjust the input tray to match your document size.

Select the Fold Type: Choose from preset options (e.g., letter fold, gate fold) or customize settings.

Adjust Guides and Rollers: Ensure alignment to prevent misfolds.

Run a Test: Always test with a single sheet to verify accuracy.

Process Documents: Feed the stack into the machine and let it work!

Most modern machines feature intuitive touchscreens and error-detection systems to minimize downtime.

Key Factors in Selecting Your Ideal Paper Folding Machine

Performance Requirements

Volume & Speed: Assess your daily/weekly folding needs. Low-volume users (e.g., small offices: <1,000 sheets/hour) may opt for manual or semi-automatic machines, while high-volume operations (e.g., print shops: >5,000 sheets/hour) require industrial-grade, automated systems.

Fold Types & Complexity: Identify required folds (e.g., letter, accordion, double parallel, z-fold). Choose machines with customizable programs for versatility. Some models handle multi-step folds in a single pass.

Paper Compatibility: Ensure the machine supports your paper sizes (e.g., A4, legal, tabloid) and weights (e.g., 20–130 lb bond). Heavyweight paper or cardstock may need specialized rollers.

Operational Efficiency

Automation & Integration: Automatic feeders, stackers, and sensors reduce manual labor. Prioritize machines compatible with existing printers, inserters, or mailroom systems for seamless workflows.

Ease of Use: Look for intuitive interfaces (touchscreens, preset programs) and minimal training requirements. Quick-adjust mechanisms for fold positioning save time.

Maintenance & Reliability: Opt for easy-to-clean designs with accessible parts. Check lubrication needs and jam-recovery features. Durable steel frames and branded components enhance longevity.

Future-Proofing & Safety

Expandability: Modular machines allow upgrades (e.g., additional fold plates, software updates) to adapt to evolving needs.

Safety Features: Ensure emergency stops, jam sensors, and overload protection to prevent accidents and downtime.

Sustainability

Energy Efficiency: Select ENERGY STAR-certified models or low-power modes to reduce environmental impact.

Recyclability: Inquire about eco-friendly materials or part-recycling programs.

Different Types of Paper Folding Machines

480TS/600TS Pharmaceutical Insert folding machines

It is designed to handle light-weight pharmaceutical and miniature leaflet folding. In order to meet different customers’needs, have 480TS and 600TS for the first station . Different width format with 4-20 plates. The second station is to handle the thick and small-size leaflets with 4/6/8 buckle plates , also can be matched with pressing unit, parrallel knife, lableing , HHS cold gluing , Hot melt gluing and vertical stacker.

Max. Infeed paper size :480*1000mm/600*1000mm

Mini. Infeed paper size :100*130mm

Mini. folded product size :30*30mm

Max. folding speed :220m/min

760TS Combi paper Folding Machine

The 760TS is AOQI’S new combi folding machine.It is designed for full size to 16p or 32p paper sheet , signature ,flyers or others various books. There are pallelt feeder and continuous feeder for your choice. The first station is with 4 buckle plate for parallel fold or first fold . The knife is equipped with independent servo motor.

Max. Infeed paper size :760*1080mm

Mini. Infeed paper size :150*180mm

Max. folding speed :210m/min

360T/480T Automatic paper folding machine

AOQI 360T/480T paper folding machines are designed for various paper with small format.For your folding needs , it can be connected with AOQI independent knife for the final cross fold and the vertical stacker to collect the folded products orderly.

Max. infeed paper size: 360*1000mm / 480*1000mm

Mini. infeed paper size:50*100mm

Paper weight : 30-250g

Max. folding speed: 200m/min

Mini. folded size: 20*50mm

The 530TS Book folding machine is largely utilized for folding various kinds of paper sheets and is especially design for wide-ranging booklet folding. It can be specified with six plates in the second station or independent knife folding unit in the second or third station.

Max. infeed paper size:530*1000mm

Mini. infeed paper size:70*120mm

Mini. folded size:22*70mm

The 570T Series Paper folding machines are specifically designed for large-format paper folding, offering exceptional cost-effectiveness to meet diverse customer needs. Equipped with an advanced automatic lubrication system and coupling, it effectively protects the core gear components, reducing wear and tear. This ensures prolonged machine life and long-term stable, high-performance operation, making it the ideal choice for businesses looking to enhance productivity while minimizing maintenance costs.

Max. infeed paper size:570*1000mm

Mini. infeed paper size:50*100mm

Mini. folded size:20*50mm

Conclusion

A paper folding machine can be a valuable investment for businesses who regularly handle large quantities of paper folding. It offers significant time and labor savings, consistent and precise folds, versatility, and cost-effectiveness in the long run. By understanding what a paper folding machine is, its benefits, how to use it, and the different types available, you can make an informed decision about whether it is worth the investment for your specific needs. Whether you are a small business owner looking to streamline your office operations or a large printing company in need of high-volume folding solutions, there is a paper folding machine out there that can meet your needs and help you improve your efficiency and productivity.