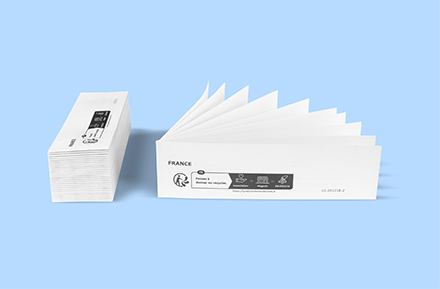

In the meticulously regulated pharmaceutical industry, every component of a drug product is critical—not only the active ingredient but also the information that ensures its safe use. This vital information is contained within the package insert, a leaflet that accompanies every medication. Pharmaceutical insert folding machines are highly specialized, automated systems engineered to accurately and efficiently fold these paper inserts to the exact dimensions required for insertion into medication boxes, blister packs, or bottles.

Definition of Pharmaceutical Outsert folding machines

Pharmaceutical insert folding machines are automated systems that precisely and rapidly fold small, thin medication leaflets or information sheets. They often incorporate optical inspection systems to guarantee accuracy and prevent misfolded inserts from being packaged with pharmaceuticals.

AOQI’s 480TS/600TS Pharmaceutical Insert Folding Machines exemplify this precision: they can achieve a minimum folded product size of 30*30mm—small enough for tiny drug containers—while maintaining consistent fold angles and alignment. This level of accuracy ensures every leaflet meets the tight dimensional requirements of pharmaceutical packaging.

Why They Are Essential

The manual processing of package inserts is virtually nonexistent in modern pharmaceutical manufacturing due to inefficiency and error risk. Here’s why these automated machines are indispensable:

1. Precision Folding

Package inserts can be lengthy documents that must be reduced to a very small, uniform size through a complex series of folds (e.g., accordion or gate folds). An imprecise fold can cause the leaflet to be too bulky to fit into its box or, more seriously, can obscure critical text. These machines execute every fold with micrometer-level accuracy, guaranteeing each leaflet is perfectly uniform.

2. High Volume Production

Pharmaceutical production lines are designed for immense throughput, often packaging tens of thousands of units per shift. Manual folding is incapable of matching this pace. Insert folding machines are built for continuous, high-speed operation, seamlessly synchronizing with other equipment like cartoners to maintain production flow and meet stringent output targets without creating a bottleneck.

3. Error Prevention

In an industry where a mistake can have serious consequences, the absence of an insert is a major compliance failure. A missing leaflet means a patient is deprived of vital safety information, potentially leading to medication errors, product recalls, and harm. Automated folding machines virtually eliminate this risk by ensuring every package receives its insert.

4. Adaptability

A single packaging line often handles multiple products, each with its own unique insert size, paper stock, and fold pattern. Modern folding machines are designed for flexibility. With quick-change tooling and digital settings, operators can swiftly switch between different product jobs, drastically reducing downtime and enhancing overall line efficiency.

Key Features & Technologies

1. Miniature Folding: Precision-engineered folding plates and rollers handle complex, small-scale folding tasks with consistent results.

2. Air (Vacuum) Feeding: Non-marking suction systems gently handle delicate paper, ensuring damage-free feeding into the folding mechanism.

3. Optical Inspection: Vision systems verify content accuracy, print quality, and fold precision, automatically rejecting defective leaflets.

4. Double-Sheet Detection: Sensors detect and reject multiple sheets during feeding, preventing missing inserts in subsequent packages.

5. Automated Systems: PLC-controlled integration with packaging lines enables seamless communication with other equipment, creating a fully automated process.

Conclusion

Pharmaceutical insert folding machines are vital components in drug packaging, providing the precision, speed, and quality assurance necessary for patient safety and regulatory compliance. These automated systems ensure every medication package contains perfectly folded, critical information, playing an essential role in maintaining pharmaceutical product integrity worldwide.

FAQ

Q1: What are the core technical highlights of these folding machines?

A: The key highlights are the combination of high-precision miniature folding technology and a fully automated quality control system. The latter includes optical inspection, double-sheet detection, and vacuum feeding, ensuring zero-defect production even at high speeds.

Q2: How does the machine ensure it doesn’t fold the wrong version of the insert?

A: Through an integrated optical inspection system (OCR/OCV). Cameras scan specific areas of the insert (such as product code or name) before folding and compare them with preset correct information in the system. If a version mismatch is detected, the leaflet is automatically rejected, ensuring only the correct inserts proceed to the packaging stage.

Q3: How long does it take to change over the machine for a different product?

A: This depends on the machine’s level of automation. Modern high-end models support "recipe-based quick changeover," where invoking a new product’s folding program from the control console automatically adjusts guides and folding tools, typically completing within minutes. Traditional models may require mechanical part changes, taking slightly longer, around 15-30 minutes.