Pharmaceutical inserts—also known as package inserts (PIs) or patient information leaflets (PILs)—are critical documents containing drug safety, dosage, and usage details. Their folding is not arbitrary; it must balance regulatory compliance, packaging compatibility, and user-friendliness. Below is a breakdown of the common folding methods for these inserts, the reasons behind their use, and how specialized machines like those from AOQI streamline the process.

Common Folding Methods

Pharmaceutical inserts are typically folded using several standard methods depending on the insert size, layout, and packaging requirements. The most common folding techniques include:

1. Parallel Fold

This is the simplest and most common folding style. The paper is folded multiple times in the same direction, creating a compact, rectangular leaflet. It’s often used when the insert must fit into narrow or elongated boxes.

2. Cross Fold

In a cross fold, the paper is folded first in one direction and then perpendicularly. This creates a compact grid-like structure suitable for large documents with extensive text. Cross folding helps maintain a balanced thickness, preventing bulkiness in small packages.

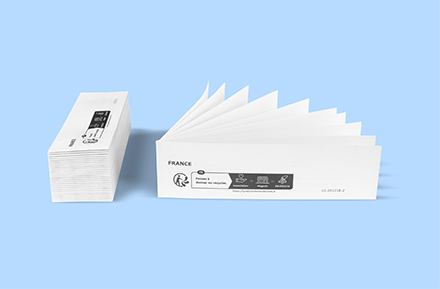

3. Pharmaceutical (Leperello or Zigzag) Fold

The zigzag or accordion-style fold allows the leaflet to unfold easily without tearing. It is ideal for patient-friendly inserts where readability and convenience are essential.

4. Combination Fold

Some inserts use a mix of parallel and cross folds to achieve ultra-compact results while preserving legibility. This approach is especially useful for multilingual instructions or products requiring regulatory information in multiple regions.

Why These Folds Are Used

Pharmaceutical companies select specific folding types for both functional and regulatory reasons. The main objectives include:

- Compactness: Inserts must fit into small cartons without adding bulk.

- Readability: Folding must ensure that text remains properly aligned and easy to read once unfolded.

- Automation Compatibility: Consistent folds enable high-speed automatic packaging lines to operate smoothly.

- Regulatory Compliance: Some countries require information to appear in a specific order or format, influencing the folding pattern.

By optimizing the folding design, manufacturers can balance these factors efficiently while maintaining quality and safety standards.

Aoqi Pharmaceutical Insert Folding Machines

To achieve the high accuracy and speed required in pharmaceutical production, companies rely on advanced folding equipment such as Aoqi’s Pharmaceutical Insert Folding Machines.

Aoqi’s machines are engineered for precision micro-folding, capable of handling ultra-thin papers as light as 40 gsm while ensuring consistent alignment and crease quality. These machines support multiple folding configurations — including parallel, cross, and zigzag folds — to meet diverse packaging demands.

Key advantages include:

- High Folding Accuracy: Servo-controlled systems guarantee precise positioning for every fold.

- High-Speed Operation: Suitable for large-scale pharmaceutical production lines.

- Flexible Setup: Quick adjustment for different folding patterns and paper sizes.

- Quality Assurance: Minimal paper damage and perfect fold alignment for professional results.

Thanks to automation, Aoqi folding machines enhance production efficiency while maintaining compliance with stringent pharmaceutical packaging standards.

Conclusion

Pharmaceutical insert folding is a highly technical process combining precision design, regulatory compliance, and advanced machinery. From simple parallel folds to complex cross folds, each method serves a purpose — ensuring that essential medical information is accessible, legible, and securely packed. With cutting-edge solutions like Aoqi’s Pharmaceutical Insert Folding Machines, manufacturers can achieve accuracy, speed, and reliability — essential for today’s fast-paced pharmaceutical industry.