Paper folding machines are essential equipment in printing, mailing, and packaging industries, helping businesses achieve consistent, accurate, and high-speed folding results. Understanding different fold types allows users to choose the best layout for brochures, letters, manuals, and promotional materials. Below are the most common fold types used in paper folding machines.

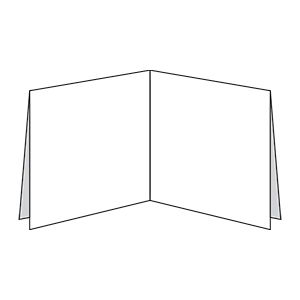

Half Fold (Bi-fold or Single Fold)

The simplest fold type: a sheet of paper is folded once along its centerline, resulting in two equal parts (e.g., an A4 sheet folded into A5). It is widely used for simple promotional leaflets, product catalog covers, and basic notices.

Common uses: greeting cards, menus, programs, simple brochures.

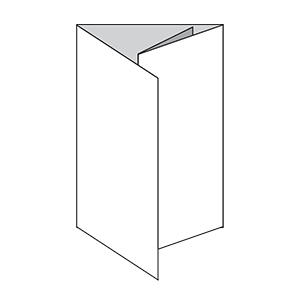

Tri Fold (Letter Fold, C Fold)

This fold type divides the paper into three equal parts through two parallel folds. It includes Letter Fold (the two ends fold inward toward the center, forming a "stacked" structure, common in pharmaceutical inserts and business letters) and C Fold (the paper folds outward in a "C" shape, suitable for brochures that need to be inserted into envelopes).

Common uses: business letters, marketing brochures, mail inserts.

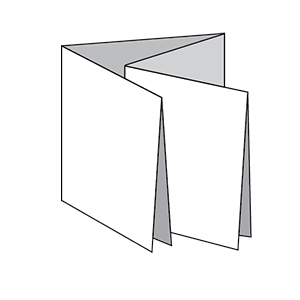

Z Fold (Accordion Fold)

The paper is folded alternately inward and outward, forming a "Z" shape when viewed from the side. This fold keeps content sequential and easy to read when unfolded, making it suitable for multi-page product introductions, event schedules, and technical specifications.

Common uses: flyers, invoices, step-by-step guides.

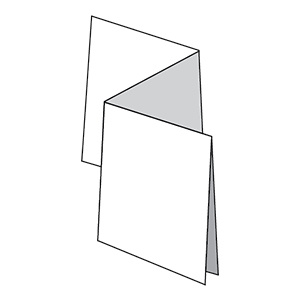

Inside Quarter Fold

The paper is first folded in half (Half Fold), then folded inward again along the centerline of the folded sheet, resulting in four layers with the folded edges on the inside. It is used for compact small-size materials like mini manuals, gift cards, and product warning labels.

Common uses: compact brochures, instruction manuals.

Quarter Fold (French Fold)

The paper is first folded horizontally (along the long side) into two parts, then vertically (along the short side) into two parts, forming a square with four layers. It is commonly used for high-end printed materials like greeting cards, art brochures, and luxury product booklets.

Common uses: invitations, maps, newsletters.

Quarter Pocket Fold (Roll Fold)

The paper is folded three times continuously in the same direction, forming a "pocket" at one end to hold business cards, coupons, or small flyers. It is widely used in promotional materials for banks, telecommunications, and retail industries.

Common uses: marketing leaflets, multi-panel product brochures.

Half – Tri Fold

A combined fold: the paper is first folded in half (Half Fold), then folded into three parts (Tri Fold) along the folded edge. This balances compactness and content capacity, suitable for multi-page leaflets like restaurant menus, educational brochures, and medical guides.

Common uses: bulky brochures, catalogs, user manuals.

Half – Z Fold

The paper is first folded in half (Half Fold), then folded into a Z-shape (Z Fold). This fold combines the compactness of Half Fold and the sequential readability of Z Fold, suitable for long-content materials that need to fit into small spaces (e.g., product installation guides, travel brochures).

Common uses: step-by-step instruction sheets, medical inserts, specification sheets.

Aoqi Paper Folding Machines

Aoqi Paper Folding Machines are designed to handle a wide range of fold types with high accuracy and stability. Whether you need half fold, tri fold, Z fold, or advanced combination folds, Aoqi machines deliver reliable performance, user-friendly controls, and efficient production speeds. Their durable structure and advanced feeding system ensure smooth processing even for high-volume printing environments.

Core Advantages

1. Extreme Customization: Supports ultra-small sizes (15mm), custom fold types, and matching of auxiliary devices (die-cutting, gluing, stacking), adapting to pharmaceutical, cosmetic, and electronic industries.

2. Precision & Stability: Equipped with CCD detection, ultrasonic double-sheet control, and three-hole suction feeding, achieving ±0.25mm accuracy and reducing material waste.

3. High Efficiency & Durability: Non-stop paper loading, 200-220m/min high speed, and automatic oil supply (imported bearings/gears) minimize downtime and extend machine life.

4. Global After-Sales Support: 18-month standard warranty, lifetime technical support, 15-day fastest shipping, and online/offline service worldwide (spare parts available for 2019 models).

5. Trusted Certification: All machines hold CE certification; the factory passes SGS audits, with 4,500+ global customers and annual sales exceeding 5.8 million USD.

Conclusion

Understanding the different fold types helps users choose the best option for brochures, letters, manuals, and marketing materials. From simple half folds to complex combination folds, paper folding machines greatly improve consistency and productivity. With versatile equipment like Aoqi Paper Folding Machines, businesses can achieve professional, precise, and efficient folding for various applications.

FAQ

Q1. What is the most commonly used fold type?

The tri fold (C fold) is one of the most popular options for brochures and business letters.

Q2. Can one paper folding machine handle all fold types?

Many modern folding machines can perform multiple folds, but capability varies by model. High-end machines like those from Aoqi support a wide range of standard and combination folds.

Q3. What factors affect fold quality?

Paper thickness, grain direction, fold settings, and machine adjustment accuracy all influence folding quality.

Q4. Which fold is best for mailing?

Tri fold and Z fold are commonly used because they fit standard envelopes.

Q5. Are combination folds more difficult to produce?

Yes, combination folds like Half–Z Fold or Half–Tri Fold require precise machine settings and stable feeding to ensure accuracy.